Energy Solutions

We understand the principles of energy conservation and offer a wide variety of energy conservation solutions.

Centrifugal Compressor Central Chillers

We work closely with Thermal Care an industry worldwide leader in process cooling technology.

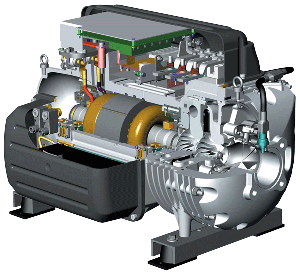

TC Series Centrifugal Central Chillers use revolutionary, frictionless, magnetic bearing Turbocor compressors to deliver optimum chiller performance and part load efficiencies. This translates into the quietest, most reliable, and most energy efficient chillers ever built. Models are available with either single or completely independent dual refrigeration circuits.

Central Chiller Equipment Features:

- 60 to 540 tons (water cooled and remote condensor models available)

- Powerful PLC Control System maintains stable and reliable operation of the chiller

- C-CUL, 508A listed and labeled industrial control panel

- Rotary Circuit Breakers for each compressor

- Centrifugal Compressor Design

Integrated Variable Speed Motor Control

- Enhances temperature control capability for partial load performance

- Soft-start control reduces peak energy demand and extends motor life by lowering initial current inrush at start-up

- Lowest noise level. Whisper quiet sound levels with 71 dBA (per compressor) and virtuall no structure-born vibration

- Compare the sound of a typical screw compressor with the centrifugal compressor

Oil Free Operation

- Eliminates oil management system and all related maintenance costs

- No potential for oil contamination of refrigerant

- Lower energy required can save up to 40% in annual operating costs when compared to screw-type compressors

Magnetic "Friction Free" Bearings

- Equipment life is extended since there is no contact with surfaces as the shaft rotates

- Compressor senses a power failure as a normal shutdown. Internal capacitors and rotational energy allow the motor to become a generator and provide a fail safe shutdown

Integrated Computer Control

- Premium control interface has 79 points of diagnostic information per compressor

- Provides extensive sensing capabilities and monitors compressor bearing and shaft positions six million times per minute

- Comunications package allows for remote diagnostics of the chiller

- Understands the differences between an industrial process chiller and a HVAC chiller

- How to evaluate the cost of operating an air cooled vs a water cooled chiller

Thermal Care Chillers

- TS Series Central Chillers - 20 to 100 tons

- MX Series Central Chillers - 50 to 500 tons

- TC Series Central Chillers - 60 to 540 tons

- PA Series Outdoor Central Chillers - 10 to 490 tons

Contact us about Centrifugal Compressor Central Chillers and let us help you calculate your Energy Saving!

MX Series Central Chiller

Efficient frictionless

Centrifugal compressor

Centrifugal compressor